- The Vitruvian Plant: Powering the Future #10-2284

-

Background

History of Nuclear Energy Nuclear Agencies and Regulations Nuclear Power in the Public Eye Economics of Nuclear Energy Radioactivity Basics Nuclear Reactor Basics Current Reactor Designs Processing Radioactive Materials Remote Handling Uses of Radiation Archimedes Filter Technology New Generation Reactors

- Components

- Project

Processing Radioactive Materials

Processing of nuclear waste is a procedure that allows specific materials to be seperated from the rest of the waste. There are many different types of processing procedures that can be liquid based, gas based, or solid based. Liquid processing relies on chemical reactions to seperate the materials.

Nuclear Fuel Reprocessing

PUREX Separation

Purex (Plutonium and Uranium Recovery by Extraction) Nuclear Separation is a process used for the reprocessing of spent nuclear fuel. The main goal of this process is to separate uranium and plutonium from nuclear fission products and spent nuclear fuel. The first step of this process is the dissolution of irradiated fuel in aqueous nitric acid. The next step is to transfer the used uranium and plutonium into an organic phase through intensive mixing with an organic solvent extraction. The organic solvent is 30 percent tributyl phosphate (TBP) that is found in kerosene. While the uranium and plutonium is mixed with the organic solvent the fission products are left in the aqueous nitric phase. The next steps of the process enable the separation of uranium and plutonium from one another.UREX Separation

UREX (Uranium Extraction) is a nuclear waste separation method that is a modification of the more widely used PUREX method. This modification prevents the extraction of plutonium from the spent fuel of a nuclear reactor. This process is done through adding a plutonium reductant to the first metal extraction step of the PUREX process. This method separates 99.9% of the uranium and 95% of the Technetium from the other fission products. The main proponent of the UREX process is the addition of acetohydroxamic acid (AHA) to the extraction sections of the process. AHA diminishes the extractability of Plutonium, thus providing greater proliferation resistance that the plutonium extraction process of the PUREX Method.DIAMEX Separation

DIAMEX (Diamide Extraction) nuclear waste separation is an extraction alternative to TRUEX, which is a derivative of the PUREX process, using malondiamide as the main component of the process. In the DIAMEX process all minor actinides and lanthanides are extracted in the process. The DIAMEX process doesn’t form organic waste. Such organic waste is burned without the formation of acidic acids and can be a factor that contributes to acid rain.SANEX Separation

SANEX (Selective Actinide Extraction) nuclear waste separation process is a derivative of the PUREX process. The SANEX process controls the management of minor actinides in the PUREX process. The SANEX process removes the lanthanides and trivalent minor actinides from the PUREX process. If actinides such as americium are to be reused for industrial sources or as fuel all of the lanthanides must be removed.UNEX Separation

The UNEX (Universal Extraction) process is a derivative of the PUREX process that is designed to remove the most unwanted radioisotopes from the remaining uranium and plutonium that is in the separation system. The UNEX process uses the mixture of cesium and strontium with poly ethylene oxide and cobalt carborane anion.GE-Hitachi Advanced Recycling Center

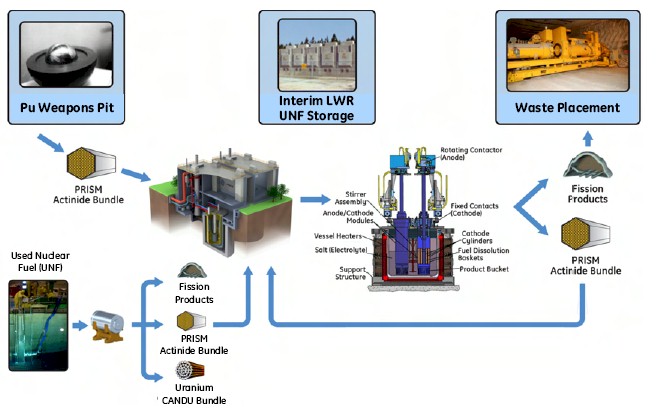

In an attempt to solve the problem of spent nuclear fuel General Electric has designed

a recycling center for nuclear waste. They plan on using this design to embrace

public and worker safety as well as decrease the impact on the environment The Advanced Recycling Center (ARC) will tackle the problem

of used nuclear fuel by recycling waste rather than reprocessing it. This will consume

all transuranic elements and reduce the emissions of greenhouse gases. The ARC separates

spent nuclear fuel into three parts: Uranium, fission products (with a shorter half-life)

that are stabilized in glass or metallic form for geologic disposal, and transuranics

which are used in the Advanced Recycling Reactor (ARR).

Through the electrometallurgical process the ARC separates spent nuclear fuel into a uranium CANDU bundle, leftover low mass fission products, and a PRISM (Power Reactor Innovative Small Modular) bundle. The fission products are stored while the uranium CANDU bundle is sent to another reactor capable of using it. The PRISM bundle is put through the ARR and recycled through the process. Through this process the ARC will be able to produce 100 times more energy than the one time through uranium cycle.

Through the electrometallurgical process the ARC separates spent nuclear fuel into a uranium CANDU bundle, leftover low mass fission products, and a PRISM (Power Reactor Innovative Small Modular) bundle. The fission products are stored while the uranium CANDU bundle is sent to another reactor capable of using it. The PRISM bundle is put through the ARR and recycled through the process. Through this process the ARC will be able to produce 100 times more energy than the one time through uranium cycle.

Nuclear Enrichment

The U-235 isotope

is gold to the nuclear engineer as he tears apart a Uranium supply in order to find

a fission material capable of fueling a nuclear reactor. Given any Uranium sample

it is estimated that on average it will only contain 0.7% of isotope U-235, with

the remainder being U-238. Both isotopes contain 92 protons and electrons, but it

is the amount of neutrons that make a difference; U-238 contains 146 while U-235

contains 143. The fewer neutrons the isotope has the easier it becomes to bombard

an atom and make it fissionable. When a particle fissions it releases other neutrons

as it falls apart; U-235 releases more when bombarded. These released neutrons then

hit other isotopes of Uranium thereby creating what is called a chain reaction. This chain reaction is favored as it releases

larger and larger amounts of energy. In order to reach an optimal reaction level

Uranium must be enriched in order to increase the ratio, at least 40%, between U-235

isotopes and U-238 isotopes.

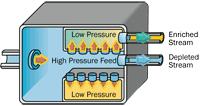

There are a variety of ways by which to enrich Uranium. A common method used here in the USA is Gaseous diffusion. In this process uranium hexafluoride (UF6) gas is pumped through a series of custom filters called porous membranes.The enrichment begins as UF6 gas molecules merge with the U-234 and U-235 isotopes to slide through through the porous membranes, that heavier U-238 isotopes find difficulty fitting through. To insure the right isotope is collected hundreds of barriers are placed in tight structure, until a collection container is met where the gas is condensed into enriched and non-enriched fuels fluids.

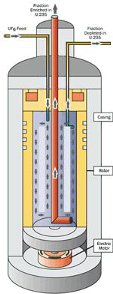

Another method for enrichment is gas centrifuge. Gas centrifuge is a process involving a series of large rotating cylinders that swing undesirable U-238 isotopes to a collective outside cylinder.UF6 gas is used once again as an agent substance to help push the U-238 isotopes to the outer edges of the centrifuge mechanism. Once rotating at a high enough speed the lighter U-235 gas molecules collect closer in the center where it is funneled into a collection tank.

There are a variety of ways by which to enrich Uranium. A common method used here in the USA is Gaseous diffusion. In this process uranium hexafluoride (UF6) gas is pumped through a series of custom filters called porous membranes.The enrichment begins as UF6 gas molecules merge with the U-234 and U-235 isotopes to slide through through the porous membranes, that heavier U-238 isotopes find difficulty fitting through. To insure the right isotope is collected hundreds of barriers are placed in tight structure, until a collection container is met where the gas is condensed into enriched and non-enriched fuels fluids.

Another method for enrichment is gas centrifuge. Gas centrifuge is a process involving a series of large rotating cylinders that swing undesirable U-238 isotopes to a collective outside cylinder.UF6 gas is used once again as an agent substance to help push the U-238 isotopes to the outer edges of the centrifuge mechanism. Once rotating at a high enough speed the lighter U-235 gas molecules collect closer in the center where it is funneled into a collection tank.

Advanced Recycling Center - Solving the Used Nuclear Fuel Dilemma

http://www.gepower.com/prod_serv/products/nuclear_energy/en/downloads/Advanced_Recycling_Center_Technology_Update_-_GEA17804%5B2%5D.pdf

Argonne's pyroproccessing technology

http://www.anl.gov/Media_Center/Frontiers/2002/d1ee4.html

DIAMEX Solvent Behavior under Continuous Degradation and Regeneration Operations

http://pubs.acs.org/doi/abs/10.1021/bk-2010-1046.ch021

Demonstration of a SANEX Process

http://www.informaworld.com/smpp/content~content=a909032313

Demonstration of the UREX Solvent Extraction Process with Dresden Reactor Fuel

http://sti.srs.gov/fulltext/ms2003089r1/ms2003089r1.html

Electrorefining

http://dictionary.reference.com/browse/electrorefining

Fractional crystallization

http://dictionary.reference.com/browse/fractional+crystallization

GE Hitachi Nuclear Energy Advanced Recycling Center

http://www.ecomagination.com/technologies/ge-hitachi-nuclear-energy-advanced-recycling-center

GE Hitachi Press Release

http://www.genewscenter.com/Press-Releases/GE-Hitachi-Nuclear-Energy-s-Advanced-Recycling-Center-Recognized-for-Its-Potential-to-Make-Energy-out-of-Used-Nuclear-Fuel-2bae.aspx

Gas Centrifuge Uranium Enrichment

http://www.globalsecurity.org/wmd/intro/u-centrifuge.htm

NRC: Uranium Enrichment

http://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html#2

NRC: Uranium Enrichment

http://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html#2

Nuclear Waste Management using Electrometallurgical Technology

http://www.ne.anl.gov/research/nwmuet/unit_process_modeling/

Nuclear engineering handbook

http://books.google.com/books?id=EMy2OyUrqbUC&pg=PA350&lpg=PA350&dq=UNEX+nuclear&source=bl&ots=Sbye3Rm-EZ&sig=NYzTQDXfnWiRoELhCJ2-BAk8jmo&hl=en&ei=uCQ3TdvfJsHngQftw93CAw&sa=X&oi=book_result&ct=result&resnum=3&sqi=2&ved=0CCIQ6AEwAg#v=onepage&q=UNEX%20nuclear&f=false

PUREX process

http://www.euronuclear.org/info/encyclopedia/p/purex-process.htm

Processing of Used Nuclear Fuel

http://www.world-nuclear.org/info/inf69.html

Radiation Chemistry of Acetohydroxamic Acid in the UREX Process

http://sti.srs.gov/fulltext/tr2002283/tr2002283.html

Uranium Hexafloride (UF6)

http://web.ead.anl.gov/uranium/guide/uf6/index.cfm

Uranium: Its Uses and Hazards

http://www.ieer.org/fctsheet/uranium.html

What Is Enriched Uranium?

http://www.ehow.com/video_4756358_what-enriched-uranium.html