- The Vitruvian Plant: Powering the Future #10-2284

-

Background

History of Nuclear Energy Nuclear Agencies and Regulations Nuclear Power in the Public Eye Economics of Nuclear Energy Radioactivity Basics Nuclear Reactor Basics Current Reactor Designs Processing Radioactive Materials Remote Handling Uses of Radiation Archimedes Filter Technology New Generation Reactors

- Components

- Project

New Generation Reactors

Starting around 1950 the United Kingdom and the United States created the first nuclear reactors. Despite an overwhelming advance in technology, nuclear reactor technology has remained ultimately unchanged. New age nuclear reactor types fall into three categories: new light water reactors, small modular reactors, and the Generation IV Industries.

Next Generation Light-Water Reactors

A reactor is an array of thin, four-meter-long nuclear rods stacked in the center

of the cask. Contiguous with each group of rods is a pressurized vessel filled with

non-affected, or light, water. Each of the four rods is filled with Uranium-235 fuel pellets which when in close proximity with

one another emit a large quantity of neutrons and heat. The function of the water

surrounding the rods is to cool the nuclear fuel to keep from a meltdown and slow

down the speed of neutron emission. The water of the reactor acts as both the cooling

and the moderating agent.

There are two main types of light water reactors: pressurized water reactors(PWR), which were created by Westinghouse Electric Corp., and boiling water reactors, which were pioneered by General Electric. PWRs currently control the nuclear reactor landscape. The newest form of PWRs is Westinghouse’s AP1000, which is the only new PWR to be approved by the U.S. Nuclear Regulatory Commission.

There are two main types of light water reactors: pressurized water reactors(PWR), which were created by Westinghouse Electric Corp., and boiling water reactors, which were pioneered by General Electric. PWRs currently control the nuclear reactor landscape. The newest form of PWRs is Westinghouse’s AP1000, which is the only new PWR to be approved by the U.S. Nuclear Regulatory Commission.

AP1000

Image courtesy of: IEEE |

The AP 1000

produces fuel through heat that converts water into steam which spins a turbine

thus creating the energy. This design has drastically improved the safety features

of standard PWR.

A conventional PWR uses motor-powered valves and water pumps to remedy accidents whereas the AP1000 has safety measures such as airflow, varied pressure, and gravity. This improved cycle reduces the pressure and temperature caused by reactions.

Westinghouse is currently building four AP1000s in China. The Sanmen 1, which will be finished in 2013, will be the first operating AP1000. The U.S. plans to build six units which, pending the approval of the NRC, will be unveiled in 2016.

A conventional PWR uses motor-powered valves and water pumps to remedy accidents whereas the AP1000 has safety measures such as airflow, varied pressure, and gravity. This improved cycle reduces the pressure and temperature caused by reactions.

Westinghouse is currently building four AP1000s in China. The Sanmen 1, which will be finished in 2013, will be the first operating AP1000. The U.S. plans to build six units which, pending the approval of the NRC, will be unveiled in 2016.

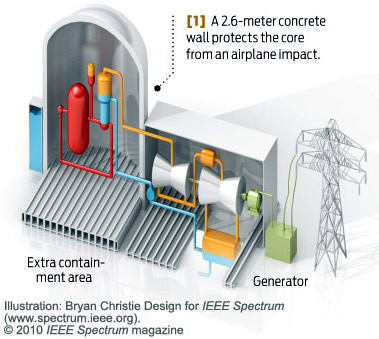

Evolutionary Power Reactor

Image courtesy of: IEEE |

The Evolutionary Power reactor(EPR) is similar in nature to

the PWR but is substantially larger. The EPR turbines can be maintained while it

is functioning which will result in little downtime during its 60-year lifespan.

The EPR is considerably safer against potential attacks than today’s PWRs. The EPR

has the highest efficiency, 36 percent, of converting thermal energy into electricity.

Four EPR’s are currently under preliminary construction, one in both Finland and France, and two in China. The Finnish reactor is scheduled to be the first completed EPR. The U.S. plans to build a minimum of four EPRs pending the NRC reviews.

Four EPR’s are currently under preliminary construction, one in both Finland and France, and two in China. The Finnish reactor is scheduled to be the first completed EPR. The U.S. plans to build a minimum of four EPRs pending the NRC reviews.

Small Modular Reactors

As opposed to the traditional nuclear power plants, which had a large focus on the

mass amount of energy converted from single large plants, small modular reactors provide a more sizable and less financially

risky personalized reactor. These reactors have the capabilities of using remote

locations that are off the grid as a destination to create energy for the much larger

metropolises. Small modular reactors allow for one of the modules to be closed for

maintenance while the other modules generate energy, thus avoiding costly, long

periods of down time designated to revamping already existing reactors.

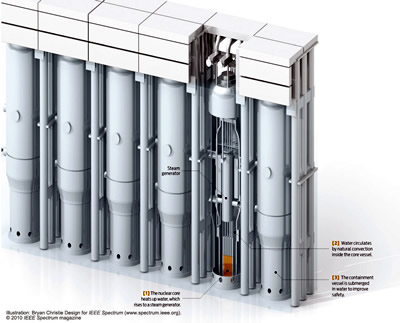

Nu Scale

Image courtesy of: IEEE |

The Nu Scale reactor

is a modular light water reactor that is geared toward replacing coal- and gas-fired

plants. In a Nu Scale reactor the uranium fuel assemblies sit inside the larger

module which is surrounded by water. The Nu Scale reactor is based on convection

as opposed to the usual light water reactor. The Nu Scale reactor first heats the

water which flows up to the top of the core vessel, then transfers the generated

heat to steam generators which then descends to the bottom to repeat the cycle.

The steam created fuels the electrical generators. After losing the energy the steam

created is cooled back into liquid, after the liquid is created it flows back into

the steam generators thus repeating the process.

The Nu Scale reactor has many features that prove to be advantageous to the ever-growing nuclear renaissance. The cooling system relies primarily on water convection which bypasses the need for pumps. The reactor plants are able to be resized to any desired quantity of modules, anywhere from 1 to 24. Each of these modules can be separately refueled which allows for zero down time between maintenance thus allowing a continuous energy flow. The steam generator is placed in a water-filled steel cask which allows for higher pressures and temperatures than the original PWRs. Nu Scale reactors are scheduled to be unveiled and operational in 2018 after preliminary certification through the NRC, which is set for 2012.

The Nu Scale reactor has many features that prove to be advantageous to the ever-growing nuclear renaissance. The cooling system relies primarily on water convection which bypasses the need for pumps. The reactor plants are able to be resized to any desired quantity of modules, anywhere from 1 to 24. Each of these modules can be separately refueled which allows for zero down time between maintenance thus allowing a continuous energy flow. The steam generator is placed in a water-filled steel cask which allows for higher pressures and temperatures than the original PWRs. Nu Scale reactors are scheduled to be unveiled and operational in 2018 after preliminary certification through the NRC, which is set for 2012.

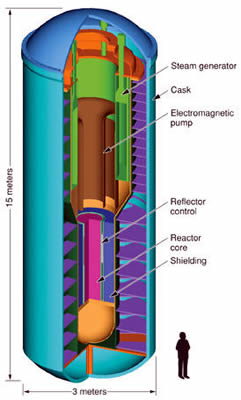

Hyperion Power Module

Image courtesy of: IEEE |

The Hyperion

Power Module (HPM) will have a thermal output of 70 megawatt and an electrical

output of 25 MW. The HPM’s core, 1.5 meters wide by 2.5 meters tall, is sealed at

the factory so that there is no chance for contamination. The core operates at a

temperature of 500ºC so there will be little risk of a meltdown due to the cooling

pipes breaking down. Modules can also be combined to increase their output and replace

a medium or large nuclear reactor. The Hyperion Power Module can last between 5 and 15 years without being refueled.

The main fuel source of the Hyperion Power Module is 20% enriched uranium nitride fuel. The mini-reactor would be cooled with lead-bismuth. This would, along with the highly enriched fuel, classify it as a fast neutron reactor. Hyperion is also able to use ceramic nitride fuel instead of the conventional uranium oxide because of its superior thermal and neutronic properties.

One of the sites at which the prototype module is being tested is the Savannah River Site at South Carolina. The prototype will be functional by 2020. The cost of the construction and operation of the prototype is estimated to be $50 million, which is about $2000 per kilowatt produced.

The main fuel source of the Hyperion Power Module is 20% enriched uranium nitride fuel. The mini-reactor would be cooled with lead-bismuth. This would, along with the highly enriched fuel, classify it as a fast neutron reactor. Hyperion is also able to use ceramic nitride fuel instead of the conventional uranium oxide because of its superior thermal and neutronic properties.

One of the sites at which the prototype module is being tested is the Savannah River Site at South Carolina. The prototype will be functional by 2020. The cost of the construction and operation of the prototype is estimated to be $50 million, which is about $2000 per kilowatt produced.

Generation IV Reactors

The most extravagant and revolutionary of the new-aged nuclear reactor types are

the Generation

IV reactors. These reactors use an array of newly innovated fuel and moderators, fast neutron reactors

get rid of the moderator process altogether. These neo-reactors contain a higher level of fuel and concentrations

of fissile materials, such as plutonium and uranium 235, than the light water reactors

do. These Reactors hold the promise of utilizing not only the initial fuel but also

the spent waste of previously used fuel to create energy.

The concept of a "breeder-burn" reactor was first proposed in 1958 by physist Saveli M. Feinberg.

The idea was not picked up again until the late 1970’s and still only on a theoretical level. Not until the late 1990’s did the reactor concept begin to get some serious interest when Lawrence Livermore Labs found a method in which breed-burner waves could travel through a fuel supply. In 2006 Intellectual Ventures, a company backed by Bill Gates, started developing detailed ideas on engineering specs, costs and feasibility in the creation of Traveling Wave Reactor.

The TWR offer many advantages over a LWR (Light Water Reactor),

Toshiba 4S

Image courtesy of: IEEE |

Toshiba 4S stands for super, safe, small, and simple this

design is comparable to a 30 year long nuclear battery. The core of the Toshiba

4S reactor has a ring shaped reflector that progressively advances over a long period

of time. This shielding agent keeps uranium 235 neutrons contained in a specific

area of the core of the reactor which is where the chain reactions take place. As

the ring advances upward it burns the uranium 235 slowly. In efforts to fully harness

the heat the 4S reactor is configured with three loops. In the first of the three

loops liquid sodium circulates through the reactor to act as a cooling agent. The

second loop also contains the liquid sodium cooling agent which transfers the existing

heat to the third loop which contains water and steam that fuels the turbine that

creates the energy. The Toshiba 4S reactor is able to be buried 30 meters underground

to provide safety against any environmental hazards and terrorists.

The Toshiba 4S reactor is vastly advantageous due to its many structural advances. The reactor is able to remain unattended for approximately 30 years which is a much higher longevity than any of its predecessors. This is possible due to the non corrosive properties of the liquid sodium coolant. The non pressurized design allows for there to be no chance of any pipes breaking which would normally cause a catastrophic explosion. The 4S reactor also utilizes its own spent fuel which would decrease the levels of cost and waste. The Toshiba Company plans to execute their implementation in the US as soon as the NRC approves their Reactor design which is set to be reviewed in late 2012.

The Toshiba 4S reactor is vastly advantageous due to its many structural advances. The reactor is able to remain unattended for approximately 30 years which is a much higher longevity than any of its predecessors. This is possible due to the non corrosive properties of the liquid sodium coolant. The non pressurized design allows for there to be no chance of any pipes breaking which would normally cause a catastrophic explosion. The 4S reactor also utilizes its own spent fuel which would decrease the levels of cost and waste. The Toshiba Company plans to execute their implementation in the US as soon as the NRC approves their Reactor design which is set to be reviewed in late 2012.

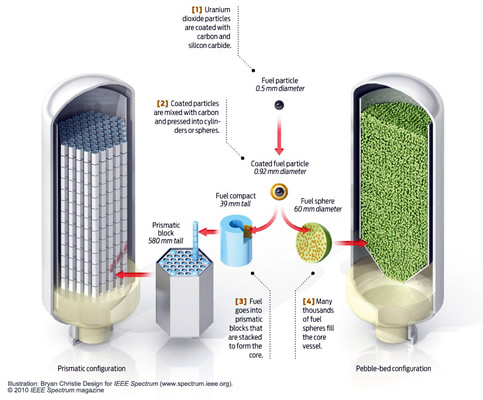

Next Generation Nuclear Plant

Image courtesy of: IEEE |

Next Generation

Nuclear Plant is designed to have the abilities to manufacture electricity

and heat to fuel the industrial applications of any thriving metropolises. The Next

Generation Nuclear Plant utilizes tristructural isotropic uranium particles (TRISO) to fuel

its Reactors. The TRISO particles are contained in blocks or spheres which also

house carbon, these blocks or spheres are then arranged into the Reactors nuclear

core thus producing the desired chain reaction. Helium is widely used in this reactor

as a coolant to remove heat from the core. The helium is also used to drive the

reactors turbines. Due to the core’s helium and graphite structure it is able to

withstand temperatures as high as 900+°C.

The Next Generation Nuclear Plant’s capability of maintaining high temperatures could provide the necessary heat that is used in petroleum refining, chemical manufacturing of plastics and fertilizers, and hydrogen production. This ability allows the reduction of carbon emissions and the use of fossil fuels. The reactors of the Next Generation Nuclear Plant use 1/5 of the power of a PWR to operate despite its vastly higher temperatures. The increased levels of heat increase the carbon’s neutron absorbing abilities, thus allowing the carbon to act as a failsafe safety mechanism. In as early as 2011 the US Department of Energy plans to implement one of the proposals from General Atomics and Westinghouse.

The Next Generation Nuclear Plant’s capability of maintaining high temperatures could provide the necessary heat that is used in petroleum refining, chemical manufacturing of plastics and fertilizers, and hydrogen production. This ability allows the reduction of carbon emissions and the use of fossil fuels. The reactors of the Next Generation Nuclear Plant use 1/5 of the power of a PWR to operate despite its vastly higher temperatures. The increased levels of heat increase the carbon’s neutron absorbing abilities, thus allowing the carbon to act as a failsafe safety mechanism. In as early as 2011 the US Department of Energy plans to implement one of the proposals from General Atomics and Westinghouse.

Power Reactor Innovative Small Module (PRISM)

Power Reactor Innovative Small Module (PRISM), a liquid metal-cooled “mini reactor”, designed and

produced by GE-Hitachi, is a generation IV reactor capable of producing

311 MWe. The PRISM was originally designed for the DOE laboratories in the advanced

liquid-metal fast breeder reactor (ALMR) program. This design is special in the

fact that no US fast neutron reactor had yet generated 66 MWe, much less commercially.

The reactor uses electrometallurgical reprocessing to remove all transuranic elements to leave fresh fuel with plutonium remaining. The used PRISM fuel is later recycled for better fuel efficiency.

The advertised plant concept is integrated into the Advanced Recycling Center, which uses six of these reactors to produce 1866 MWe.

The reactor uses electrometallurgical reprocessing to remove all transuranic elements to leave fresh fuel with plutonium remaining. The used PRISM fuel is later recycled for better fuel efficiency.

The advertised plant concept is integrated into the Advanced Recycling Center, which uses six of these reactors to produce 1866 MWe.

Small Secure Transportable Autonomous Reactor (SSTAR)

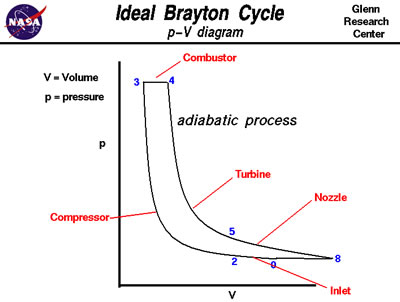

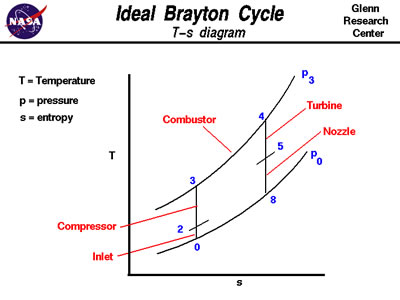

The SSTAR micro-reactor is a smaller, modified version of the

STAR reactor, and is based on the design of a

lead-cooled fast reactor. SSTAR was developed by Lawrence

Livermore, Argonne, and Los Alamos National Laboratories. The cooling system for

this reactor can be lead-based, Lead-Bismuth-based (Pb-Bi), or sodium-based, all of which are more

thermally efficient than using traditional water-based coolants. To function properly, the reactor must be placed

below ground level. When first developed, its power output ranged from 10 to 100

MW. Later it was changed to generate power of 45MWt or 20MWe in response to the

generation IV reactor push. This reactor can run for up to 30 years before it must

be refueled or shut down for recycling. It would be 12-meters high by 3.2-meters

in diameter and weigh no more than 500 tons. A prototype is projected to be tested

by 2015. They would also like to merge this reactor with the Brayton Cycle turbine

which uses supercritical carbon dioxide. This

Brayton cycle describes how a gas turbine functions with the following four

stages: adiabatic expansion, isobaric compression, adiabatic compression, and isobaric

expansion.

The spent fuel, in the form of uranium or plutonium, stays in the reactor to supply 30 years of power. The recycling part of this reactor eradicates the majority of the waste in the reactor's core. This reactor also has many passive safety systems which automatically shut the reactor down should it fail. The NRC plans to approve the SSTAR by a new process called license-by-test rather than the normal license-by-design, in which it will have to pass a test in a vulnerable situation such as reactor overload.

|

|

| Images courtesy of: NASA | |

The spent fuel, in the form of uranium or plutonium, stays in the reactor to supply 30 years of power. The recycling part of this reactor eradicates the majority of the waste in the reactor's core. This reactor also has many passive safety systems which automatically shut the reactor down should it fail. The NRC plans to approve the SSTAR by a new process called license-by-test rather than the normal license-by-design, in which it will have to pass a test in a vulnerable situation such as reactor overload.

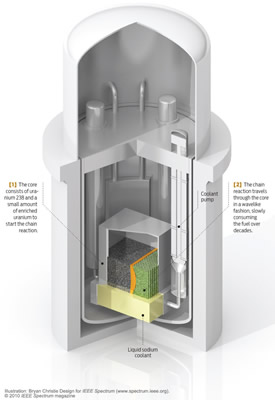

TerraPower TP-1

The TWR is a sodium cooled nuclear reactor which uses 238U (depleted Uranium) to generate its nuclear reaction. It is referred to as breeder-burn reactor; in which the depleted uranium is transmuted into Plutonium through a series of nuclear reactions. The Plutonium then undergoes fission releasing a large amount of energy into the coolant. Electricity is then generated when the coolant passes through a standard heat exchanger.The concept of a "breeder-burn" reactor was first proposed in 1958 by physist Saveli M. Feinberg.

The idea was not picked up again until the late 1970’s and still only on a theoretical level. Not until the late 1990’s did the reactor concept begin to get some serious interest when Lawrence Livermore Labs found a method in which breed-burner waves could travel through a fuel supply. In 2006 Intellectual Ventures, a company backed by Bill Gates, started developing detailed ideas on engineering specs, costs and feasibility in the creation of Traveling Wave Reactor.

The TWR offer many advantages over a LWR (Light Water Reactor),

- It uses depleted Uranium, needing only a small amount of enriched uranium to begin the breeder-burn wave.

- The reaction sends the wave done along hexagonal fuel supply consuming the Plutonium it generates so that proliferation of highly feasible materials is not an issue.

- The wave moves slowly and reactions only a small segment of the fuel, allowing energy production that can last upwards of 100 years.

- Can be scaled to different size reactors from 300MW as high as 1000MW.

- The core temperature in the sodium cooled reactor reaches 550 deg C, allowing for a more efficient exchange of energy.

The TerraPower TP-1 reactor produces a new aged nuclear reaction

wave that creates and utilizes its own fuel that can last decades at a time. In

the TerraPower TP-1 a cylindrical or parallelepiped core reactor is filled with

uranium

238 and small traces of enriched uranium, which acts as an ignition source.

The

enriched uranium igniter creates the preliminary flow of neutrons which

in turn creates the chain reaction process. Due to the structural shaping of the

reactor and the atomic properties of uranium the reaction travels in a wave like

motion through the core of the reactor at a rate of 2-3 centimeters per year from

one end to another. This wave like motion consists of two major reactions: the initial

reaction transforms the uranium 238 into plutonium 239, the second of the two reactions

fissions the plutonium thus producing increased levels of neutrons and heat.

The TerraPower TP-1 reactor allows for enrichment and reprocessing of uranium, thereby creating energy while reducing the risks of doing both tasks at a separate time in two separate locations. The reactor utilizes spent uranium fuel as an energy source which allows for much larger amounts of energy from the same amount of uranium. Not only can the TerraPower TP-1 reactor use fuel from previous reactions it can also use spent fuel from light water reactors. One load of fuel can last for many decades thus minimizing the refueling and refurbishing processes. The initial TerraPower TP-1 project started in 2006 but expects a test reactor to be ready in 2020.

The TerraPower TP-1 reactor allows for enrichment and reprocessing of uranium, thereby creating energy while reducing the risks of doing both tasks at a separate time in two separate locations. The reactor utilizes spent uranium fuel as an energy source which allows for much larger amounts of energy from the same amount of uranium. Not only can the TerraPower TP-1 reactor use fuel from previous reactions it can also use spent fuel from light water reactors. One load of fuel can last for many decades thus minimizing the refueling and refurbishing processes. The initial TerraPower TP-1 project started in 2006 but expects a test reactor to be ready in 2020.

Image courtesy of: IEEE |

A New Paradigm for Power Generation

http://www.hyperionpowergeneration.com/product.html

AP1000

http://www.ap1000.westinghousenuclear.com/

Advanced Boiling Water Reactor

http://www.gepower.com/prod_serv/products/nuclear_energy/en/new_reactors/abwr.htm

Advanced Nuclear Power Reactors

http://www.world-nuclear.org/info/inf08.html

Advanced Recycling Center

http://www.gepower.com/prod_serv/products/nuclear_energy/en/downloads/Advanced_Recycling_Center_Technology_Update_-_GEA17804%5B2%5D.pdf

Burns and Roe Awarded Conceptual Design of the TP-1 Reactor Plant

http://www.roe.com/news_article.asp?ArticleID=195

Generation IV Nuclear Energy Systems

http://www.ne.doe.gov/geniv/neGenIV1.html

Generation IV Nuclear Reactors

http://www.world-nuclear.org/info/inf77.html

High Fidelity Nuclear Energy System Optimization Towards an Environmentally Benign, Sustainable, and Secure Energy Source

http://prod.sandia.gov/techlib/access-control.cgi/2010/106684.pdf

Hyperion Power Generation Reactor Design

http://nextbigfuture.com/2009/11/hyperion-power-generation-reactor.html

Hyperion Unveils Design of its Small Modular Nuclear Reactor

http://www.greencarcongress.com/2009/11/hyperion-20091121.html

Hyperion to build small modular reactor at Savannah River

http://www.nucpros.com/content/hyperion-build-small-modular-reactor-savannah-river

Ideal Brayton Cycle

http://www.grc.nasa.gov/WWW/K-12/airplane/brayton.html

Introducing Traveling-Wave Reactors

http://intellectualventures.com/Libraries/TerraPower/IV_Introducing_TWR_February_2010.sflb.ashx

Next Generation Nuclear Plant

http://www.nextgenerationnuclearplant.com/

Next Generation Nuclear Plant Project

http://www.nextgenerationnuclearplant.com/pressroom/publications/d/CDocuments_and_SettingsBenjmlDesktopEPRI_Tech_Update_NGNP_1016759.pdf

NuScale

http://www.nrc.gov/reactors/advanced/nuscale.html

Nuclear Power Plant Fuel

http://www.nei.org/howitworks/nuclearpowerplantfuel/

Nuclear Reactor Renaissance

http://spectrum.ieee.org/energy/nuclear/nuclear-reactor-renaissance/0

Nuclear energy to go: A self-contained, portable reactor

http://www.eurekalert.org/features/doe/2004-07/dlnl-net071204.php

Pressurized Water Reactor

http://www.nucleartourist.com/type/pwr.htm

Review of Toshiba 4S Sodium-Cooled Nuclear Power Reactor

http://www.yritwc.org/Portals/0/PDFs/nuclearreactorletterucs.pdf

Safe, modular, scalable nuclear power generation

http://www.nuscalepower.com/

Shaw and Westinghouse Hit Milestone

http://nuclearstreet.com/nuclear_power_industry_news/b/nuclear_power_news/archive/2010/01/12/shaw-and-westinghouse-reach-critical-milestone-at-unit-1-of-sanmen-ap1000-nuclear-site-in-china-01121.aspx

Small Nuclear Power Reactors

http://www.world-nuclear.org/info/inf33.html

TR10: Traveling-Wave Reactor

http://www.technologyreview.com/energy/22114/

TerraPower Update

http://atomicinsights.blogspot.com/2010/06/terrapower-update-latest-series-b.html

The Element Uraniuim

http://education.jlab.org/itselemental/ele092.html

The Energy Blog

http://thefraserdomain.typepad.com/energy/2006/06/the_latest_nucl.html

The Very-High-Temperature Reactor

http://www.gen-4.org/Technology/systems/vhtr.htm

U.S.NRC

http://www.nrc.gov/

Under The Hood With Duncan Williams - GE Hitachi's PRISM Reactor

http://nuclearstreet.com/nuclear_power_industry_news/b/nuclear_power_news/archive/2010/01/20/under-the-hood-with-duncan-williams-ge-hitachi-prism-reactor-01201.aspx

Under the Hood With Duncan Williams - Toshiba 4S

http://nuclearstreet.com/nuclear_power_industry_news/b/nuclear_power_news/archive/2010/01/27/under-the-hood-with-duncan-williams-toshiba-4s-01272.aspx

Uranium Enrichment

http://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html

Westinghouse

http://www.westinghousenuclear.com/