|

Mainland High School

Lord of the Trash Rings: ISTF 09-2004 |

||||||||||||||||||||

|

Home

Introduction Contest Components One Two  Product Product

Three Background Environmentalism History of Plastics Marine Laws Plastic Properties Pollution Laws Research Groups The Oceans Waste Management Project Assessment Team |

Properties of Plastic

Plastic Industry

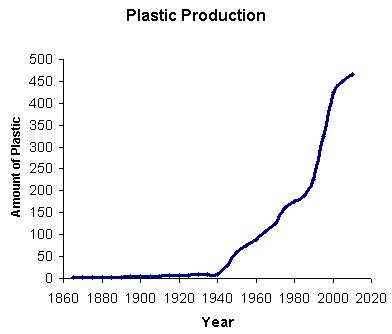

The growth of the production of plastic since its initial creation in 1868 has been

a series of unsteady increases. These increases are usually a response to a series

of worldly events. Early on the popularity of plastics spread at a constant rate

as knowledge of making them increased. An observable trend before plastics first

initial boom is seen around the Great Depression. When the Great Depression occurred

there was more of a demand for cheaper ways of production for an overall economic

stimulus.

However, plastic's negative trend during this period outweighed its demand

because there was more of a demand in the public necessity and less of a demand

in entertainment such as plastic toys and lavish accouterments. Another reason why

plastics sales were down during this period was because of a reduced production

of plastic packaging since export rates were down.

Another contingent catalyst on the growth of plastics was the boost in production during World War II.

WWII got America out

of the depression it was experiencing and spread the technology of plastic via weaponry

causing a three fold increase in plastics production from 1940 to 1945.

Being in recessions and depressions always causes a lack of production to happen.

In every recession a slight percentage decrease in growth is

observed, as shown in the late 1900s for plastics which caused a sort of plateau effect. This in coordination with new scientific

discoveries of plastics' harmful effects on people in society and the environment

has spawned this trend. The graph to the right shows our plot of the previously

discussed trends.

Types of Plastic

There are

seven major categories of plastics, all with different physical and chemical

properties.

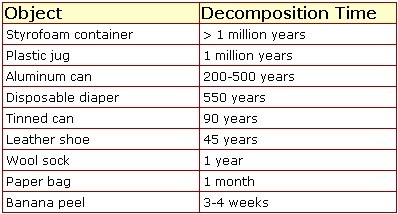

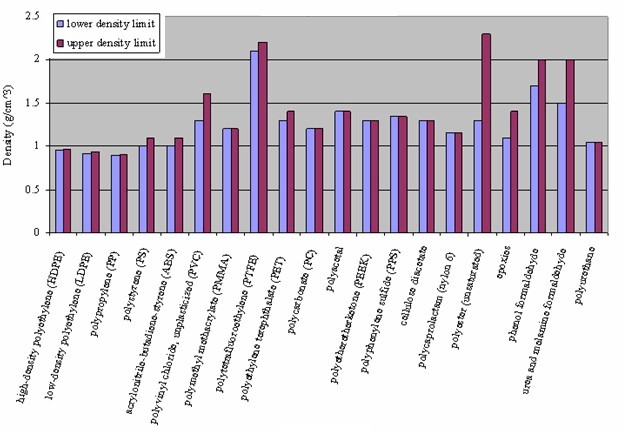

As shown below, most plastics have a density hovering between 0.8-1.5 g/cm3. This image is courtesy of Evan I.  All of the plastics listed above are recyclable and have many different uses even after being recycled. Most of these plastics are also used for some sort of packaging, whether it be bottles, or packing peanuts to protect a package. Unfortunately, all of these plastics eventually find their way into the ocean or a landfill because the recycling process isn't 100% efficient. This means that we cannot completely reuse all of the results of the recycling process. Plastic Decomposition is the ability of plastic to separate or resolve into constituent parts or elements over time. It is unfortunate that plastics take such a long time to decompose, if they do at all. The table below shows the average time for certain plastics to decompose compared with other degradable objects. Again, unfortunately, plastic takes a very long time to degrade and decompose. This has inspired quite a bit of research but the person to find the best results with their experiments was a boy, a junior in high school, named Daniel Burd, who discovered microbes that could completely breakdown and decompose a plastic bag in three months. There are plastics that take, from what we can guess, over a million years to degrade; but do they ever really go away? Plastic, when broken down, just gets smaller and smaller. It never actually goes away. These little tiny bits and pieces of plastic whose diameter is less than twenty microns, are the true danger to our oceans. The phytoplankton and zooplankton are being outnumbered by the enormous amounts of plastic within our oceans. Our fish are dying from yet to be processed nurdles. In the last few years though, there has been promise in the research. There are now compostable/biodegradable plastics. There are companies that have recently begun mass producing an additive to put into your compost that assists the microbes in their task of breaking down the plastic. Most of these "biodegradable" plastics however, are just claimed to be biodegradable, but really, they just break down into very very small particles that we talked about earlier. There are now corn starch based plastics that has been certified as compostable.

Recycling

The recycling of plastics can be

grouped into industrial scrap recycling and post-use plastics. Industrial scrap

reprocessing is the collection of scraps from the assembly line to be injected back

into the beginning of the process. Everything else is referred to as

post use recycling. It includes the collection of waste plastics from industries,

retailers, and consumers. Of the 69 million pounds of plastic recycled in 2008,

35.8 million was post industrial, 28.5 million was post commercial, and 5.1 million

was post consumer.

After the plastics are collected, they are organized based on a resin coding system – the familiar symbol of a number surrounded by a triangle of arrows – designed by the Society of the Plastics Industry. The numbers range from one to seven and represent the inherent difficulty in recycling that particular type of plastic. Plastics are cleaned, its labels are removed, and then it is sent to the main arc of the recycling process where it is recycled either chemically or mechanically. To mechanically recycle plastics, the plastics are shredded, cleaned, seperated, melted, and either converted to pellets - nurdles - or directly remade into new products. If it is chemically recycled, the plastic is treated with heat and other chemicals to break down the plastic on a molecular level, resulting in the basic constituents of the original plastic. Eventually, the plastics are put back on the market in such various products as water bottles, pipes, and egg cartons. If the plastic is melted down without being previously separated, it is sold as a lumber substitute due to its wood-like characteristics.

Nurdles

Nurdles are pre-production plastic resin pellets; these are essentially the

building blocks of all plastic products. They are about the size of fish eggs making

it very easy for marine life to mistake them for food. Ingestion of these pellets

can lead to intestine blockage and starvation as well as the possibility of poisoning.

Over 250-billion pounds of nurdles are shipped out each year,

and during transport is when most pellets become airborn and travel into the ocean.

Unfortunately nurdles represent about 10% of the litter counted on beaches world

wide.

A Brief History of Plastic http://www.brooklynrail.org/2005/05/express/a-brief-history-of-plastic Earth 911: Plastic http://earth911.com/recycling/plastic/ Feedstock Recycling of Plastic Waste http://books.google.com/books?id=HUlLAvuGsoQC&printsec=frontcover&source=gbs_navlinks_s#v=onepage&q=&f=false Governor Schwarzenegger Signs AB 258, the “Nurdles Bill” http://www.healthebay.org/news/2007/10_18_ab258signed/default.asp Litter Facts and Research http://mdc.mo.gov/nomoretrash/facts/ Plastic Marine Debris: What We Know http://marinedebris.noaa.gov/info/plastic.html Plastics Recycling http://www.bpf.co.uk/Sustainability/Plastics_Recycling.aspx Plastic Resins Industry Hit Hard By Global Economic Recession in 2008 http://www.americanchemistry.com/s_acc/sec_policyissues.asp?CID=996&DID=9827 Plastic Statistics http://www.indianplasticportal.com/plastic-statistics/ Recycling is already in action. http://www.epspackaging.org/index.php?option=com_content&view=article&id=10&Itemid=7 Recycling Symbols http://www.earthodyssey.com/symbols.html Safe Use Of Plastic Food Packaging And Containers http://www.ava.gov.sg/FoodSector/FoodSafetyEducation/Food+Facts/SafeUsePlasticContainers/index.htm Society of Plastics Industry http://www.plasticsindustry.org/ SubsTech Plastics Recycling http://www.substech.com/dokuwiki/doku.php?id=plastics_recycling Turning Plastics to Biodegradable Plastics http://www.ecopure.biz/news/turning-plastics-to-biodegradable-plastics U.S. Expansions and Recessions: A Historic Look, 1900-2007 http://seekingalpha.com/article/47291-u-s-expansions-and-recessions-an-historic-look-1900-2007 Waste Online http://www.wasteonline.org.uk/resources/InformationSheets/Plastics.htm What's a Nurdle? http://weblog.greenpeace.org/oceandefenders/archive/2006/11/whats_a_nurdle.html |