|

Mainland High School

Suitable for a Disaster: ISTF 08-1835 |

||||||

|

Home

Introduction Contest Components One Two  Product Product

Three Fabrics History of Fabrics Smart Fabric Projects Sensors Nano Sensors Power Production Communication Cell Phones 3G Phones Data Transfer Helikites Interoperability Microwaves Relief Agencies Telecommunication Project Assessment Team |

Smart Textile Projects

Included in our product is a "smart suit" with various types of sensors to monitor

the vital signs of the individual wearer as well as sensors to report environmental

conditions.

Sensors currently available in smart clothes include measurements of respiration, heart rate, blood pressure, posture, internal temperature as well as skin temperature. Current sensors to monitor external conditions include temperature, chemical gases, radiation, and humidity. Most also include a GPS device to provide the wearer's location. Below are several examples of existing smart fabric projects that are under development in both the commercial sector and at university research facilities.

The SFIT Cluster (Smart Fabrics and Interactive Textiles) is a European Union consortium involving seven projects that deal with smart, flexible garments to monitor health, and provide protection and disaster management.

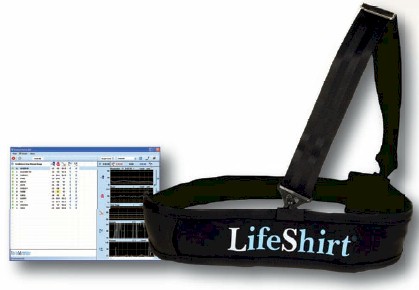

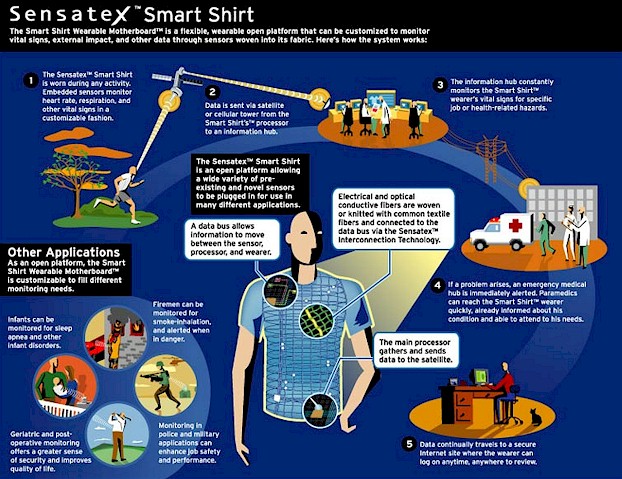

An Italian technology firm called ProeTEX is currently working with e-textiles. This company is developing "smart wearables" to protect emergency personnel, namely firefighters. The first prototype uniform includes an inner and an outer layer that cooperates to relay information to both the wearer and base crews waiting outside. The inner garment contains sensors that monitor vital signs (breathing, heart rate, core temperature). When someone wearing the uniform’s inner layer inhales (making their chest expand), pressure on the fabric increases. When the wearer exhales (making their chest compress), pressure on the fabric decreases. Sensors monitor the rhythm of increasing and decreasing pressure to relay breathing patterns. The outer garment houses external sensors for monitoring outside temperature and noxious fumes. It also holds an interconnection harness that links the sensors to alarms and Bluetooth communications all of which are housed in the "electronics box." The interconnection harness connects to a wearable (flexible) battery, a standard GPS, and an antenna that transmits information to base crews. ProeTEX plans to incorporate additional features in future prototypes. Developers hope to include monitors for pose and activity as well as sensors that detect sweat, dehydration, electrolyte levels, and stress. New sources of energy such as photovoltaic (solar) and thermoelectric (heat) will be used to improve longevity and storage of power. ProeTEX also plans to incorporate smart firefighter boots that are equipped with additional gas sensors and a back up battery. Additional ProeTEX products include a "civilian band" with abilities similar to the firefighter’s inner garment. The civilian band can be easily strapped around an injured civilian's chest to begin monitoring vital signs until medical personnel arrive. VivoMetrics sells an on-the-shelf product called the LifeShirt. Originally introduced as the VivoResponder, it provides a means to remotely monitor vital signs. The VivoResponder housed sensors that monitored respiration, heart rate, activity, posture, and skin temperature. This product was portable and had a comfortable chest strap. It was designed for "first responders such as firefighters, police, industrial clean-up workers, hazmat workers or others who work under dangerous conditions and could benefit from utilizing an integrated monitoring system." With the Vivo Responder came a computer software program called Vivo Command. This software can monitor up to 24 different units, with one person monitoring them from afar. This Vivo Command system had 5 programmable tolerances that could be set for each individual person. With these tolerances, the high and low thresholds for each category could be set uniquely for each person. When these thresholds were passed, bells, whistles, and blinking lights went off to warn the person who was monitoring the strap that something was wrong. In 2004, MIT developed waterproof computer patches. These patches contain Bluetooth, microphones, sensors, and mini-PC motherboards which help prevent soiling and staining. A handbag using different computerized fabric patches contains micro-processors, memory and either radio tranceivers, sensors, microphones, batteries, or displays. They may take the shape of squares and triangles and are coated with a hard transparent resin making them waterproof. Padding, along with the chosen fabric, incapsulates the electronics to allow Velcro to unite all of the patches. Wires from the circuit board are attached to silver-coated contacts in the Velcro; allowing data and power to flow from one module to the next. The patches would give users the capability to swap modules and create new functionality, for example, a voice synthesizer. MIT is looking to expand the funtions to include internet access and instant weather reports and warnings. Sensatex, Inc. is a life science technology company focused on Smart Textile Systems. The Sensatex SmartShirt is Sensatex's first patented project and is currently under field trials as of May 1, 2007. This shirt’s main purpose is to monitor a person's physiological information and movements (heart rate, respiration, and other vital signs). The data is sent via satellite so that an information center can monitor the wearer. Needed emergency services can be contacted to reach the SmartShirt wearer quickly. The wireless technology used for the "Smart Shirt" system using Bluetooth and WLAN. This technology in not as reliable but has great promise for monitoring. In an attempt to make a safer, more comfortable, and more "fashionable" safety helmet, Tore Christian Bjørsvik Storholmen of SINTEF, Scandinavia's largest research organization, created the "Pro Active Helmet." This helmet contains multiple features that expand the traditional helmet's protect-ability and wear-ability. An inside layer is made of stretchable, comfortable smart fabric that immediately toughens by tightening its interlocking threads to form a hard, protective shock absorber when struck. Covering the smart fabric layer is the traditional hard hat plastic material, shaped to resemble a baseball cap. Storholmen believes that construction workers will be more likely to wear their helmet if it feels more comfortable and looks more fashionable. In addition to its protective and visual features, the Pro Active Helmet includes ear protection that is more comfortable that the standard ear muffs or plugs for construction workers. A conductive loop housed within the ear piece, allows for wireless communication between workers as well as the ability to charge other instruments, such as intercom or gas detectors attached to the helmet. It even features the ability to connect to Bluetooth allowing the wearer to answer a phone call without removing his protective wear. The Bio-Suit is expected to be the next generation space suit. It is currently being researched and developed at MIT's Man Vehicle Lab. The suit would serve as a 'second skin' allowing easy movement as well as life support. This suit was designed by uniting wearable technologies, information systems, evolutionary space systems design, and biomedical breakthroughs in skin replacement and materials. The suit's life support system provides mechanical pressure to the body through a tight suit. The technology is embedded into the suits layers with a possibly recyclable outer layer. The suit has a flexible design method in order to allow changes in the hardware and software make up of the suit. The suit will be able to repair itself without loss of abilities.

Previous suit designs had joints and bearings which resulted in bulkiness and a lack of flexibility. Although the exact devices and technology that will be included in the BioSuit are uncertain, there are several possibilities being explored to solve current problems. These include electric alloy mesh, a thermal gel suit, an electric gel suit, a stretch alloy band suit, and an electric alloy zipper or remote zipper suit. Also under investigation as possible methods of thermal control are absorption packs, venting to the atmosphere, and perspiration tubes. The BioSuit was inspired by the giraffe's tight skin which regulates blood pressure. The BioSuit performs a similar function through counter pressure and is expected to be finished within 10 years. It is currently being worked on by people at MIT and can already offer 25 to 30 kilopascals of pressure to the legs. The suit is said to be safer then the old space suits. Until the suit can be used on the next mission to Mars it could be used in physical therapy exercises. Astronautix - Bio-Suit http://www.astronautix.com/craft/biosuit.htm BIOTEX - Introduction http://www.biotex-eu.com/ Bluetooth - Technology http://www.bluetooth.com/bluetooth/technology/ CONTEXT Project http://www.context-project.org/ CTIA Wireless - Fashion In Motion http://twenty1f.com/2007/03/ Digital Lifestyles - Clothing Mounted Computer Sensors Discussed by MIT http://digital-lifestyles.info/2004/10/25/clothing-mounted-computer-sensors-discussed-by-mit/ European Projects in Smart Fabrics, Interactive Textiles: sharing Opportunities and Challenges http://www.csem.ch/sfit/pdf/eu_sfit_projects_opportunities_and_challenges.pdf Information Society Technologies http://cordis.europa.eu/ist/ Institute of nano-technology - Innovations in Textiles 2009 http://www.nano.org.uk/conferences/textiles2009/overview.htm Jee Park - Smart Clothing http://ldt.stanford.edu/~jeepark/jeepark+portfolio/cs147hw8jeepark.html More Inspiration - ProActive Smart Safety Helmet http://www.moreinspiration.com/Innovation.aspx?id=3304 MVL - Biosuit http://mvl.mit.edu/EVA/biosuit/index.html MVL - Home http://mvl.mit.edu/ MyHeart Project http://www.hitech-projects.com/euprojects/myheart/home.html New Scientist - Smart fabrics make for enhanced living http://www.newscientist.com/article/dn6553 OFSETH Project http://www.ofseth.org/ Popular Mechanics - Skintight, Lightweight Spacesuit http://www.popularmechanics.com/science/air_space/4220822.html PROeTEX http://www.proetex.org/index.htm PROeTEX - Prototype O1: Inner Garment http://www.proetex.org/p1_inner_garment.htm PROeTEX - Prototype 1: Civilian Band http://www.proetex.org/p1_civilian_band.htm PROeTEX - Prototype 1: Electronics http://www.proetex.org/p1_electronics.htm PROeTEX - Prototype 1: Outer Garment http://www.proetex.org/p1_outer_garment.htm Science Daily - New Soft Safety Helmet http://www.sciencedaily.com/releases/2008/06/080611183702.htm Sensatex - Licensed Patents http://www.sensatex.com/licensed_patents.html Sensatex - Home http://www.sensatex.com/ Sensatex - Pressroom http://www.sensatex.com/pressroom.html SFIT http://www.csem.ch/sfit/ SFIT - Background http://www.csem.ch/sfit/html/background.html SFIT - Events http://www.csem.ch/sfit/html/events.html SFIT - Project Information http://www.csem.ch/sfit/html/projects.html SINTEF - About Us http://www.sintef.org/Home/About-us/ SINTEF - Tore Christian B. Storholmen http://www.sintef.no/Home/Contact-us/All-employees/?EmpId=2656 Smart Fabrics 2009 http://www.smartfabricsconference.com/ STELLA Project http://www.stella-project.de/ VivoMetrics - How Does the VivoResponder Work? http://www.vivometrics.com/hazmat/about_the_system/how_does_the_lifeShirt_work.php |