Component Two

- Give two examples and descriptions of products (and the companies

where they are produced) which are commercially available and directly related to the NCT

application your team has selected.

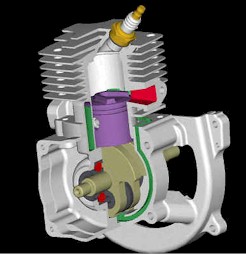

Mitsubishi Gasoline Direct Injection GDI Engine

The Gasoline Direct Injection (GDI)

system is the first attempt to use direct injection with gasoline, not diesel

fuel. It took 15 years to develop this compact engine, but in 1996 Mitsubishi

engineers Drs. Ando and Akira Kijima were finally able to present their GDI

prototype to the public. The difference between the GDI engine and the older

Otto-motors is that the fuel injection and mixing of gasoline with air take

place directly in the cylinder. This internal air/fuel mixture enables a more

exact regulation of the amount of fuel used. Since the GDI engine burns less

gasoline than carburetor engines and engines with indirect injection, it also

produces less CO2 and NOx. According to Mitsubishi, the new engine consumes 20

percent less gasoline and emits 20 percent less CO2, while its performance

increases by 10 percent. The GDI engine connects the advantages of standard

gasoline engines, quiet running and good performance,

with the advantage of a diesel engine, small consumption.

Mitsubishi is the first manufacturer to offer a gasoline engine with direct

injection in mass production and apply it to a variety of their new car models.

Approximately 37,000 GDI engines have been sold on the Japanese market so far,

and a car equipped with this new engine traveled 800 miles on only 17 gallons of

gasoline.

However, the NOx emissions did not meet the EPA requirements for the lifetime

of the engine in the U.S. market when this engine was first introduced. This

technology has been modified so that it meets the European Phase III regulations

that took effect in the year 2000, and which are similar to those of the U.S.

low emissions vehicle (LEV) standard.

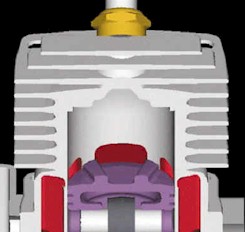

TANAKA PureFire Engine

The PureFire engine is an engine

manufactured by TANAKAŠ Power Equipment Inc. that uses centrifugal force to allow

for more efficient fuel burning. It creates this centrifugal force through the use of

curved surfaces and high velocity fuel intake.

|

|

Images used with permission of Tanaka |

The curved surfaces come in two parts: the curved top and the U-shaped device on the

piston itself. The high velocity is created by using a smaller intake. In order for the

same amount of fuel to come in, the fuel has to come in faster. It is similar to putting

your thumb over a garden hose to make it spray water farther. As the fuel charge is

circulated through the crankcase it is prepared to maximize

atomization and be placed in "the optimum range of the spark plug for flame

propagation." (R Haslam)The curved dome contributes to

more efficient fuel burning by keeping the fuel separated in a smaller space. Thus

allowing the spark plug to ignite the high quality fuel completely and use the high

quality fuel to ignite the low quality fuel, in a chain reaction that leads to a cleaner,

more complete combustion. The U-shaped component also helps herd the fuel. The spark

plug is set at an angle to the piston, so it is easier to install and take out. With most

two stroke engines, having the spark plug in the center of the top would allow a more

complete ignition. This delivery design is a low cost alternative to fuel

injection."(R Haslam)

- Identify a product or trade organization affiliated with the

products you identified, describe their mission, number of companies involved and economic

importance.

The American Society of Mechanical

Engineers was founded in 1880 and is known today as ASME International. This nonprofit

educational and technical organization serves more than 125,000 members in almost 40

countries worldwide. ASME sets many industrial and manufacturing standards. ASME's members

work in all sectors of the economy, including government, industry, and academia.

ASME International's mission is to

promote and enhance the technical competency and professional well-being of its members.

Through quality programs and activities in mechanical engineering, ASME wants to better

enable its practitioners to contribute to the well-being of humans. ASME holds 200

professional development courses and 30 technical conferences each year.

As a member of ASME, one has

the opportunity to stay informed on new standards, inventions, and breakthroughs in

mechanical engineering. ASME also offers continuing education and training courses. They

offer a financial passport, which includes group insurance, auto and homeowner insurance,

and major credit card and banking privileges. Other benefits include discounts on car

rentals, receiving ASME's publication Mechanical Engineering, and

receiving discounts on mechanical engineering publications and journals.

ASME is involved with university

students majoring in mechanical engineering. Each year they try to recruit new student

members from the universities. ASME offers a membership discount of 50% to each

professional member who recruits a student. ASME offers grants and fellowships to graduate

students who are involved in cutting-edge research. ASME also offers scholarships and

loans to college students interested in a mechanical engineering degree.

Of particular importance to our project are the ASME student chapters located at the University of Central Florida, the University of Florida, the University of Miami, and one combined for Florida State University and Florida A & M

University. Also of importance to this project is that the Environmental engineering

Division of ASME has a few publications out citing the dangers of the chemical, MTBE. One

such publication is a letter to the EPA recommending that they take action on the MTBE

problem.

Also of particular importance to our project is the Internal Combustion Engine (ICE) Division of

ASME. This division was founded in 1921 to promote the art and science of mechanical

engineering of engines. This division encourages and fosters research and

development for mobile, marine, rail, generation, and stationary applications. ICE

has also summarized and published reliable data concerning these pursuits.

- Propose a new product or process based on the team's NCT

application, provide details regarding possible customer base, suggested retail price (per

unit) and projected sales of product for years 1 through 3.

Our proposed product is a two-stroke engine [CLICK here to see details]

that integrates the following three hamonized technologies. TANAKA's crankcase and

delivery system, mechanical logic gates, and a dynamic mechanical switch. to produce an

engine which has reduced emissions and fuel economy. Personal watercrafts, motorcycles,

snowmobiles, scooters, mopeds, small cars, and electric generators are all products that

would be improved if they utilized our engine. Our new engine would cost between $1500 and

$2000. The decline in jetski sales industry wide from 200,000 units in 1995

to about 70,000 units in the year 2000 would hopefully be reversed by the introduction of our product on the market.

This reversal in the trend would be attributed to the fact that many reservoir and other public waterways would be reopened

to personal watercrafts. Consumers would be interested in replacing their two-stroke

engine with our design because it is not only environmentally friendly but also more fuel

efficient.

- Via e-mail locate a company that might manufacture your proposed

product and ask them to evaluate what you have proposed.