|

Barges

Courtesy of

Coosa-Alabama River Improvement Association, Inc.

|

The development of river commerce along the principle arteries of trade in North

America demanded a need for an efficient shipping container for that trade. American

river barges developed into their current form around 1840. The first barges where wooden-hand crafted boxes,

sealed with tar to prevent water leakage. These rudimentary barges used for shipping

raw materials quickly deteriorated. Today American river barges are manufactured

out of steel and can often be utilized for over fifty years.

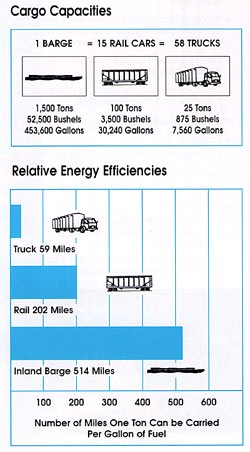

Barges are efficient and adaptable for transporting bulk materials. One barge has

the ability to transport five times its own weight, the equivalent of 15 railcars or 58 trucks. The use of barges is also extremely

fuel efficient. This allows for the transport of as many as 40 to 50 being pushed by one large towboat on the Mississippi

below St. Louis. |

There are a variety of barges on the river system. Approximately 26,000 barges are used for dry cargo; with the standard

“Jumbo

Hopper” barge being 200 ft long, 35 ft wide and 12 ft tall. The major difference

between barge types depend on which commodities they will be transporting. Other types of

barges: such as tankers, floats, flat deck, and other speciality barges, come in a variety of sizes that depend on their purpose. Typically

the lead barges in a unit tow have raked ends which are more efficient for traveling

through the water, while the barges behind are traditional box style. The average life span of a river barge is 25 years with good maintenance. The average price

of a river barge is currently around $400,000. Most barges are constructed from

3/8 to ˝ inch A-36 steel.2

Image used with the permission of David F

Image used with the permission of David F

The majority of barges are

double hulled, the outside hull touches the water and inside hull contains

cargo. The area between them is a void space.

Once barges are loaded they are lashed for transport. They are usually arranged

in a fashion conducive for the waterway they will traverse. On the Upper Mississippi,

Ohio and Illinois Rivers (North of St. Louis) barges are maximally arranged at 5 long and 3 wide. This is due to the size of

the locks used to change water elevation for successful commerce.

According to the AWO, as of December 31, 2002, there are approximately 27,500 double-hulled barges active in the towing industry.

Image used with the permission of

AWO

Image used with the permission of

AWO

The American Waterway Operators

http://www.americanwaterways.com/barges.htm

Costal Alabama River Improvement Association

http://www.caria.org/waterway_facts.html#anchor178439

http://www.caria.org/barges_tugboats.html

David Hanby

1email correspondence: February 13, 2006

2email correspondence: January 20, 2006

McDonough Marine

http://www.mcdonoughmarine.com/hopper.htm

Old River Bill

http://oldriverbillzumwalt.members.ktis.net/barges.htm

Tennessee Tombigbee Waterway

http://www.tenntom.org/iws.htm

|