|

Mainland High School

Cutting the Cord: ISTF 07-1726 |

||

|

Home

Introduction Components One Two  Product Product

Three Microwave Research W. C. Brown Generators History Phased Arrays Properties Rectennas Semiconductors Solar Satellites Superconductors Moon Research Colonization Helium-3 Fusion Geography Mining Resources Project Assessment Bibliography Glossary Team |

Mining Methods and Helium-3 Extraction

Mining in general can be categorized into two methods, underground mining and surface mining. Below you can view a graphic illustrating different mining methods.

Underground mining consists of drift, slope, and shaft mining, and actual mining techniques like room, pillar, and longwall mining.

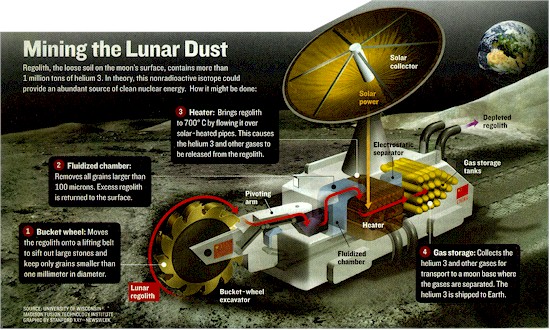

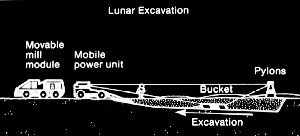

Lunar Mining and Helium-3 Extraction Before the moon can be mined the area has to be investigated. According to Charles E. Glass, there are two different types of moon areas: Apollo sites, which are the area that have been searched and documented, and generic sites, which are areas of the moon have never been visited but might have potential to mining. In other words, we would have to survey the site and take samples before we start the mining process. To survey the moon, a robot will sample and analyze the soil. U.S. roboticists have begun work on a lunar rover that can drill into the surface and take samples. This rover has to be well built to withstand harsh conditions including vast temperature changes. The rover has to operate on minimal energy levels so that it can operate in the dark areas without running out of power until the sun returns to charge the batteries through the use of solar panels. Thus, the robot has to have a lightweight body to conserve energy in the transportation process. Once the sample is analyzed the information will be sent to base for further analysis to decide if the sampled area contains a significant amount of helium to begin mining. Mining the moon is starting to be a very popular topic. The Chinese government is planning on building a mining device that has a large bucket wheel on the front which is attached to a pivoting arm. The arm allows the machine move through short distances while still collecting tons of moon dust, or regolith. Once dredged up, the regolith continues through a filter that removes any large debris, including stones. Much of the 3He will be shaken loose merely by handling the dust. After the filtration the remaining dust enters a solar heater that heats the dust up above 800 degrees Celsius, releasing any trapped gases. These gases, including 3He will be stored in containers and delivered to the moon base where the gases are separated. The leftover soil will be pumped out behind the extractor, returning it to the lunar surface. NASA's version is very similar. It is comprised of a bucket-and-reel system, or slusher system, that pulls the dirt up a ramp and into a hauler. This method has been used on Earth and is considered adaptable for use on the Moon. The top layer of the lunar surface is a glassy, powdery mix of minerals deposited by solar rays and asteroids striking the surface.

"Yes, the surface is fine and powdery. I can kick it up loosely with my toe. It does adhere in fine layers, like powdered charcoal, to the sole and sides of my boots. I only go in a small fraction of an inch, maybe an eighth of an inch, but I can see the footprints of my boots and the treads in the fine, sandy particles." Neil Armstrong, Apollo 11 (109:25:08)

The mining method used depends upon the desired goal or product. Four main issues are outlined below:

The mining of 3He from the moon would be astronomically beneficial to everyone everywhere. Gerald Kulcinski, a longtime advocate and leading pioneer in the field of fusion research at the University of Wisconsin, estimates that helium-3 would have a cash value of $4 billion a ton in terms of its energy equivalent in oil. According to Apollo 17 astronaut Harrison Schmitt, 25 tons of 3He could easily power the United States for a year. The moon will not be harmed or disfigured in any major way. Because the helium-3 only accounts for a small concentration, 20 parts per million, of the lunar dust's composition, we would be required to mine a million tons of lunar dust to produce around 70 tons of 3He. We would only be sifting through the dust, not creating any major ruts or grooves in the surface. 1st Space Exploration Conference - The Lunar Dust Problem: From Liability to Asset http://www.cden.ca/2005/2ndCDEN-conference/data/10201.pdf Apollo 11 - Lunar Surface Journal http://www.hq.nasa.gov/office/pao/History/alsj/a11/a11.step.html CBC News - Rover with Canadian-made drill to test lunar mining prospects http://www.cbc.ca/technology/story/2007/09/21/tech-rover-drill.html McGill University - A Review of Mining Technologies For Space http://www.cden.ca/2005/2ndCDEN-conference/data/10201.pdf Ministério da Ciência & Tecnologia - Fusion Reactions http://www.plasma.inpe.br/LAP_Portal/LAP_Site/Text/Fusion_Reactions.htm Nanomedicine, Volume I: Basic Capabilities - Nuclear Fusion http://www.nanomedicine.com/NMI/6.3.7.2.htm Newsweek - To Reach For The Moon http://fti.neep.wisc.edu/gallery/pdf/nw021207.pdf Permanent - Mining the Lunar Surface http://www.permanent.com/l-mining.htm Ralston Middle School - Lunar Site Characterization and Mining http://www.belmont.k12.ca.us/ralston/programs/itech/SpaceSettlement/spaceresvol3/lscam1.htm SPACE.com - Researchers and space enthusiasts see helium-3 as the perfect fuel source http://www.space.com/scienceastronomy/helium3_000630.html Star Bulletin - UH scientists envision mining town on moon http://starbulletin.com/2007/02/18/news/story02.html University of Kentucky - Bolted roof http://www.uky.edu/KGS/coal/bolt_roof.htm University of Kentucky - Continuous-mining machine http://www.uky.edu/KGS/coal/Con_miner_pic.htm University of Kentucky - Contour mining http://www.uky.edu/KGS/coal/contour1.htm University of Kentucky - Dragline http://www.uky.edu/KGS/coal/dragline.htm University of Kentucky - Methods of Mining http://www.uky.edu/KGS/coal/coal_mining.htm University of Kentucky - Surface mining http://www.uky.edu/KGS/coal/surface_mining.htm |