Piezoelectric stack actuators, also called stick-slip actuators,

are made of slices of ceramic material bonded together. This maximizes

displacement and the electric field strength while having a low driving voltage.

Stack actuators are currently used for fiber optic alignment, mirror and

electronic positioning, and cell manipulations. Sensor

Technology's multi-layer piezoelectric

actuator is a device consisting of a number of piezoelectric elements in a

stack. The elements are generally connected in parallel either through the

electrode structure or the insertion of brass electrodes between the elements.

When a voltage is applied to the assembly, it produces small displacements with

a high force capability.

Currently, there is only one modern flexible

wing being researched. NASA is testing an F/A-18 Hornet equipped with an Active Aeroelastic Wing. This wing has the ability to change the shape of it's wing

surfaces while in flight, which will provide a new measure of control and better aircraft

performance.

Boeing Phantom Works modified the test

aircraft wings at its St. Louis facility with additional actuators, a split leading edge

flap, and thinner wing skins. This would allow the outer wing panels, made of composite

material and lightweight aluminum, to twist up to five degrees. The traditional wing

control surfaces - trailing edge ailerons and an outboard leading edge flap - will be

used to provide the aerodynamic force needed to twist or "warp" the wing. In

addition, the plane has been equipped with highly sophisticated flight controls. Project

engineers hope to obtain roll performance at transonic and supersonic speeds close to that

of production F/A-18s, without using the aircraft's stabilizers (fully moving horizontal

tail flight control) and with smaller control surface deflections.

*Because of the diverse nature of our product, we

felt that AIAA was the best organization to affiliate with our project because

of its support for innovative research and development.

The American Institute of Aeronautics & Astronautics was

formed in 1963 with the merger of American Rockets Society (ARS) and the

Institute of Aerospace Science (IAS), with a

mission “to advance the arts, sciences, and technology of

aeronautics and astronautics, and to promote the professionalism of those

engaged in these pursuits.” Today the non-profit, educational based

organization has a membership of more than 31,000, all of whom have one thing in

common: devotion to the progress of engineering and science in aviation, space,

and defense. There are over 50 corporations who are

members of AIAA. Membership benefits include the

opportunity to broaden their business base in both the U.S. and international

markets and the ability to influence aerospace policy in congress.

The American Institute of Aeronautics & Astronautics was

formed in 1963 with the merger of American Rockets Society (ARS) and the

Institute of Aerospace Science (IAS), with a

mission “to advance the arts, sciences, and technology of

aeronautics and astronautics, and to promote the professionalism of those

engaged in these pursuits.” Today the non-profit, educational based

organization has a membership of more than 31,000, all of whom have one thing in

common: devotion to the progress of engineering and science in aviation, space,

and defense. There are over 50 corporations who are

members of AIAA. Membership benefits include the

opportunity to broaden their business base in both the U.S. and international

markets and the ability to influence aerospace policy in congress.

The AIAA hosts many workshops, technical meetings, management

conferences, and professional development courses each year. The AIAA

publishes six technical

journals and a whole series of college level textbooks, and a few

general interest books focused on aerospace and astronautics. The AIAA also

publishes once a month Aerospace America,

a magazine full of feature writers; critical research, developing technologies;

and features on design, electronics, materials, computer applications, science,

and policies that affect aviation, space, and defense.

The AIAA is fully committed to funding and educating anyone

interested in aviation engineering and science. The AIAA offers a total of 40

scholarships: 30 scholarships offering $2,000 to undergraduate students

and 10 scholarships offering $5,000 to graduate students. They also offer

design competitions, in which a team is to solve a real world

problem. There are five undergraduate competitions, one graduate competition, and

one open competition in which a team must design, build, and fly an airplane. Currently there are 145

active student branches set up at colleges, junior colleges, and

universities, with 12 branches in foreign countries. Currently there are 5,000 members

worldwide. The AIAA also offers students the chance to present research in a

formal technical meeting with the Regional Student Paper Conference.

There are many benefits in being a member of AIAA. Members

are encouraged to establish important professional contracts. Members are

also able to gain recognition from their peers, access comprehensive resources and research services,

and access the job opportunity

bulletin boards.

Our idea is to devise a way to change the shape of an airfoil using piezoelectrics.

The Piezo ribs are the substantive core of our product. The piezoelectric actuators themselves can transform electrical energy into massive amounts of linear force. Since these actuators are relatively small, many of them can be stacked into the wing.

If a strip were to contain 40 actuators, there would be a net change of 20°

resulting in a net force of sin(0.5°) or 0.87% of the force acting torsionally with the

remainder being linear.

This is an acceptable balance since the Piezo strips can withstand several dozen pounds of

torsional force and several tons of linear force. The

ribs convert linear force into torsional force in the following way:

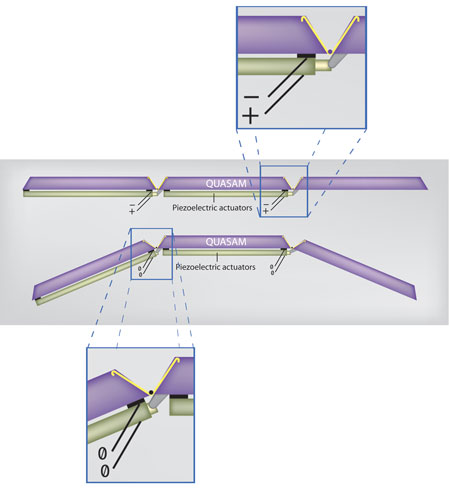

There are several "cells" consisting of a piezoelectric actuator and a QUASAM

strip. These cells are attached by a hinge and a spring. In an uncharged state, the piezoelectric actuators are slightly

smaller than their corresponding QUASAM strip. This difference in length creates

a slight angular difference between adjacent cells. This effect has been

exaggerated in the diagram below, as the true angular difference is very small. When hundreds of strips are connected in this manner, there

will be a noticeable cumulative effect.

When the pilot wants to flatten the wing, he connects a DC source of the proper

voltage to a circuit running through all of the piezo strips. This applied voltage will

increase the length of the piezo strips, which in turn will decrease the camber of the

wing. Since the piezo's are capacitors, energy would just be needed during the

actual morphing. When the wings need to re-curve, the pilot would discharge the voltage. In the event of the electrical systems failing, the wings can be

re-curved by discharging them through a closed circuit with a resistor. To summarize: to straighten the wing, a charge is run through the

piezo cells which would lengthen them; to re-curve the wing, the charge would be

removed.

Image used with permission of Sarah Carbiener

Image used with permission of Sarah CarbienerThe wing: The wing will consist of a central shaft, piezo ribs, QUASAM bars across the ribs, and a skin of QUASAM. The piezo ribs will affect the shape, the bars will provide support, and the QUASAM skin will provide a supple yet strong surface for the wing to create lift.

QUASAM: QUASAM is a general term for a family of carbon-based solids. These solids typically are light-weight, water and ice repellant, resistant to corrosion and erosion, very strong, and easily maintained. The QUASAM strips can serve another purpose. they can be stretched out along the wing, until many parallel

Piezo cells use the same QUASAM strip. This will spread the force of the piezos

along the entire wing and will also provide a hard surface for the wing.

The central shaft: The central shaft will provide an unmorphing structure for the morphing wing to attach to. It will be a

stiff QUASAM structure that is itself attached to the fuselage of the plane. It will be the strength of the wing. In addition, the QUASAM shaft will be hollow like current wings to allow fuel storage.

The piezo ribs: These ribs will spread away from the central shaft. When uncharged, the piezo actuator is a few

micrometers

smaller that the QUASAM layer. When the cells are connected, they are ever so slightly bent. The bending effect of hundreds of bars supplies the camber. The basic design of this project uses the piezoelectric effect to turn electricity into movement. However, the piezoelectric effect works both ways. Any unwanted movement in the Piezo ribs will create detectable currents in the electrical circuit that can be

measured, and translated into current, wing shape, and force.

The control system: the control system is necessary to ensure that the Piezo crystals morph into the desired wing shape and don't vary wildly with sheering forces. It will consist of manual, semi-manual, and automated controls. The manual and semi manual controls determine what the wing should be. The automated controls influence how the wing is exactly shaped.

The automated controls: These are a series of controls that more or less form a negative feedback loop to prevent the wing from bending horribly out of shape. The actual electrical circuit acts as a detector for how the wing is shaped, using electrical signals from the Piezo ribs. The computer calculates how much power needs to go into the wings and where. The power source will give a varying power output to control the exact shape of the wing.

Computer: This is where the fine-tune accuracy of the wing happens. It takes the information garnered from the electrical circuit and

calculates how much force is currently acting on the wing. It can then do quick

computations to determine how much power is needed to move wing to the most ideal shape possible.

Manual/semi manual controls: These are the controls that the pilot uses. He/she can tell the plane "I need the wing to be super

streamlined" or "I need a landing wing" and the wing will implement

the necessary changes. These controls will, in essence, replace current controls for

moveable parts in the wing, because the wing can be changed holistically.